Ecotone Systems Private Limited

Acoustic Enclosure Manufacturer in India

An acoustic enclosure, often called soundproof enclosure, is a structure designed to significantly reduce and control noise. It is mainly used in India to isolate noisy equipment like air compressors, glass crushers, blowers, turbines, and diesel generator (DG) sets. Its main purpose is to keep sound from escaping into the surrounding area, ensuring compliance and creating a controlled acoustic space. Made with heavy-duty panels, composite materials, and specialized sound-absorbing materials, the walls, floor, and ceiling of the enclosure effectively dampen sound waves. Ecotone is a leading manufacturer of acoustic enclosures in India, providing customized solutions.

High-Performance Acoustic Enclosures for Noise Control

Our expertise as acoustic enclosure suppliers covers multiple industries including power plants, manufacturing units, and processing facilities where our enclosures effectively isolate noisy equipment such as turbines, compressors, blowers, and crushers. Beyond industrial use, we also serve studios, theaters, and commercial buildings, helping clients achieve superior sound quality and comfort.

Every acoustic enclosure we build is tailored to meet your specific needs, taking into account the required noise reduction level, frequency range, and application type. Our enclosures are designed with advanced ventilation systems, easy access doors, and high-quality soundproof materials to deliver both functionality and long-term reliability.

As one of the leading acoustic enclosure manufacturers in India, we are committed to innovation, precision engineering, and customer satisfaction. Whether you need a standard solution or a fully customized enclosure, we provide the perfect blend of performance, safety, and efficiency for your project.

- Gas Turbine Enclosure

- Acoustic Enclosure for Blowers

- Glass Crusher Machine

- Air Compressor Acoustic Enclosure

- CNC Machine Noise Enclosure

- Acoustic Enclosure for Noise Generating Machine

- Punch Press Enclosure

The final design and construction must take into account the desired level of noise reduction, the frequency range of the noise, and the specific needs of the application. Key features such as proper ventilation and convenient access points are included to make sure the enclosed space is both effective and usable.

How Acoustic Enclosures Work

An acoustic enclosure is a specially engineered structure designed to reduce and control noise by using a combination of sound-absorbing and sound-blocking techniques. As a leading acoustic enclosure manufacturer in India, we design our enclosures to provide maximum noise reduction efficiency while maintaining proper ventilation and accessibility for equipment.

1. Sound Absorption (Inside)

The interior surfaces of the enclosure are lined with high-quality sound-absorbing materials such as acoustic foam, mineral wool, or perforated panels. These materials absorb sound energy by converting it into heat through friction and reflection, significantly reducing noise levels inside the enclosure.

2. Sound Blocking (Structure)

The enclosure’s structure acts as a solid sound barrier. The walls, ceiling, and flooring are made from dense materials like mass-loaded vinyl and composite panels that effectively reflect and block sound waves. This prevents noise from escaping the enclosure or entering from the external environment.

3. Precision Sealing

Every joint, corner, and access point in the enclosure is meticulously sealed to avoid any sound leakage. Acoustic gaskets, caulking, and weatherstripping are used to ensure complete acoustic integrity, preventing even the smallest sound vibrations from escaping.

4. Ventilation and Accessibility

To maintain airflow without compromising on sound insulation, acoustic louvers and silencers are integrated into the ventilation system. These ensure proper circulation of air, while soundproof glass vision panels and easy-access doors allow visibility and maintenance convenience without affecting noise control.

By combining these advanced engineering techniques, our acoustic enclosures in India create a controlled and quiet environment that minimizes noise pollution and enhances operational efficiency.

Let’s Connect: Reach Out to Us

Have a question or idea? Fill out the form and we’ll get back to you soon!

Related Posts:

Technical Features of Our Acoustic Enclosures

1. Custom-Designed Solutions: All enclosures are built in compliance with ISO 14001 and CPCB noise pollution control norms, ensuring top-quality performance and environmental safety.

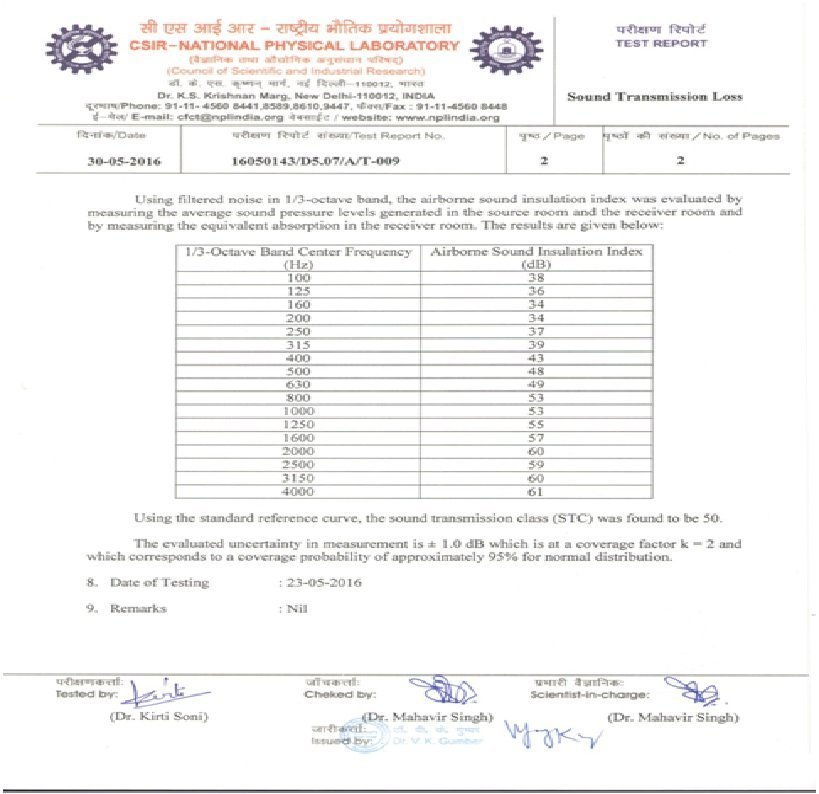

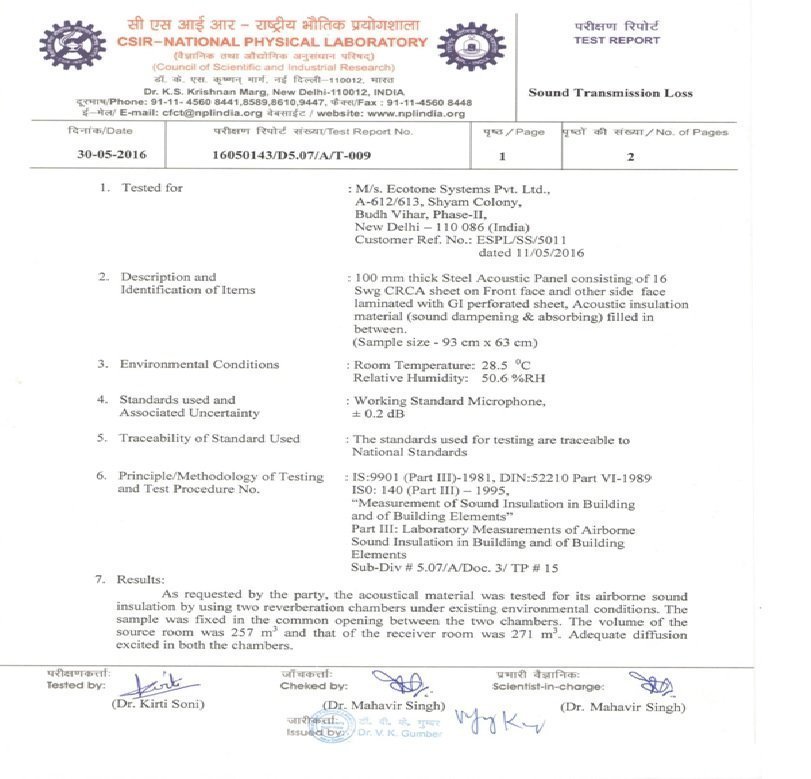

2. High STC Value Panels: Our acoustic panels achieve a 50 STC value and are tested as per IS-9901 (Part III) – 1981, DIN 52210 Part IV – 1984, and ISO:140 (Part III) – 1995 standards for superior sound insulation.

3. Durable Construction: Panels are made using 16-gauge CRCA or GI perforated sheets, offering exceptional strength, longevity, and acoustic performance.

4. Advanced Design Facility: We use AutoCAD-based design systems that include fully detailed piece-marked assemblies and precise layout drawings for every project.

5. Protective Coating: Each enclosure is coated with two layers of primer followed by automotive-grade paint in the desired color, providing corrosion resistance and a smooth finish.

6. Optimized Illumination: Integrated electrical wiring, switchboards, and lighting systems maintain an illumination level of 300 LUX inside the enclosure for safe and efficient operation.

7. Efficient Ventilation System: Designed with fresh air inlets and hot air exhausts, our ventilation systems maintain ideal temperature and airflow without compromising sound insulation.

8. Soundproof Glass Vision Panels: Each enclosure includes noise-resistant vision panels, allowing clear visibility and easy monitoring of the enclosed machinery while maintaining noise isolation.

Additional Specialized Acoustic Solutions by Ecotone Systems

Ecotone Systems also delivers a comprehensive range of additional noise-control solutions designed to meet diverse industrial and architectural needs. Our expertise extends to high-performance Noise Barriers that effectively block outdoor and industrial sound, premium Acoustic Doors engineered for superior sound isolation, durable Soundproof Curtains ideal for flexible noise reduction, and precision-built Anechoic Chambers for controlled acoustic testing. These solutions are crafted to enhance privacy, ensure comfort, and create optimized sound environments across various applications.

STC REPORTS

Get the Perfect Acoustic Enclosure Solution for Your Needs

Looking for a reliable acoustic enclosure manufacturer in India to reduce noise and improve efficiency? Our team of experts is here to design and deliver a customized noise control solution tailored to your application. Whether it’s for industrial machinery, power equipment, or commercial spaces, we provide durable, high-performance enclosures that meet ISO and CPCB standards.

FAQ

ask us anything

Who is the best acoustic enclosure manufacturer in India?

Ecotone Systems is the leading acoustic enclosure manufacturers in India, known for delivering customized, ISO and CPCB-certified soundproof enclosures for turbines, compressors, generators, and industrial machinery. Our enclosures combine durability, performance, and precision engineering to meet all industrial noise standards.

What are the main benefits of installing an acoustic enclosure?

Installing an acoustic enclosure reduces industrial noise pollution, improves worker safety, ensures CPCB compliance, and enhances equipment longevity. It also boosts workplace productivity by creating a quieter and more controlled environment.

Can acoustic enclosures be customized for specific machines?

Yes, every acoustic enclosure can be customized based on machine size, noise level, ventilation needs, and accessibility. We design enclosures for compressors, blowers, turbines, CNC machines, and other noise-generating equipment.

How much noise reduction can an acoustic enclosure provide?

Depending on design and material, a high-quality acoustic enclosure can reduce noise levels by up to 25–50 dB(A). This makes it ideal for meeting strict industrial noise regulations and improving acoustic comfort.

Completed Project: Acoustic Enclosure

Ecotone Systems successfully completed a custom-designed Acoustic Enclosure project to control excessive noise generated by high-capacity industrial equipment at a client’s manufacturing facility. The primary objective of this project was to significantly reduce noise levels while ensuring uninterrupted machine performance, proper ventilation, and ease of maintenance.

Acoustic Enclosure for Hydraulic Power Pack

Client – Surabhi Fragrances

Location – Jaipur

Acoustic Enclosure

Client – Wabtec India Industrial Private Limited

Location – Bengaluru, Karnataka

Ecotone Completed Projects

Explore our portfolio of successfully delivered acoustic solutions across diverse industries. Each project reflects our engineering expertise, attention to detail, and commitment to high-performance noise control.