Semi Anechoic Chamber | Leading NVH Chamber Manufacturer in India

As a trusted Semi Anechoic Chamber and NVH Chamber Manufacturer, ECOTONE™ delivers advanced acoustic testing environments designed for accurate noise and vibration measurement. Our chambers are engineered with a 100 Hz cut-off frequency using ECO-10 Anechoic Wedges that offer up to 0.99 absorption, ensuring superior acoustic performance.

High-Performance Semi Anechoic Chambers for NVH Testing

ECOTONE™ develops precision-engineered semi anechoic chambers specifically for automotive components and full-vehicle testing. The room structure features solid floors and walls with a fully absorbent ceiling, allowing heavy machines, engines, or vehicles to be placed naturally for accurate testing.

These chambers are widely used for vehicle run-up noise testing, steering wheel and seat rail vibration analysis, engine compartment acoustic evaluation, exhaust and intake noise measurement, structure-borne noise analysis, engine vibration testing, and powertrain mounting assessments. All ECO-10 wedges are manufactured from fire-retardant (FR) materials, ensuring long-term safety and performance.

Tests & International Standards Supported

ECOTONE™ Semi Anechoic Chambers comply with major global standards, including BS ISO 3744, ISO 3745, and BS 4196. These standards ensure highly accurate and repeatable sound power level measurements.

What is a Semi Anechoic Chamber?

A semi anechoic chamber is a specialized acoustic room designed to simulate free-field conditions by absorbing sound reflections from the walls and ceiling. Unlike a full anechoic chamber, a semi anechoic chamber retains a reflective floor, enabling real-world testing of vehicles, large equipment, and heavy machinery. This structure makes it ideal for industries such as automotive, aerospace, electronics, consumer appliances, and industrial machinery.

Enhanced Durability and Long-Term Performance

ECOTONE™ Semi Anechoic Chambers are engineered not only for precision but also for long-term durability. Each chamber is constructed using high-quality acoustic materials, corrosion-resistant metal structures, and advanced sound isolation technologies that maintain performance even under continuous testing conditions. The chambers are designed to operate efficiently for years with minimal maintenance, ensuring consistent acoustic accuracy and a dependable testing environment. This makes Ecotone a preferred choice for organizations seeking reliable NVH testing facilities that deliver stable performance over the long term.

Contact Ecotone for Acoustic Testing Solutions

Whether you need a Semi Anechoic Chamber, NVH testing setup, or a custom-designed acoustic environment, we are just a message away. Contact us today to discuss your project requirements and let our experts provide a reliable and cost-effective solution.

Let’s Connect: Reach Out to Us

Have a question or idea? Fill out the form and we’ll get back to you soon!

Related Posts:

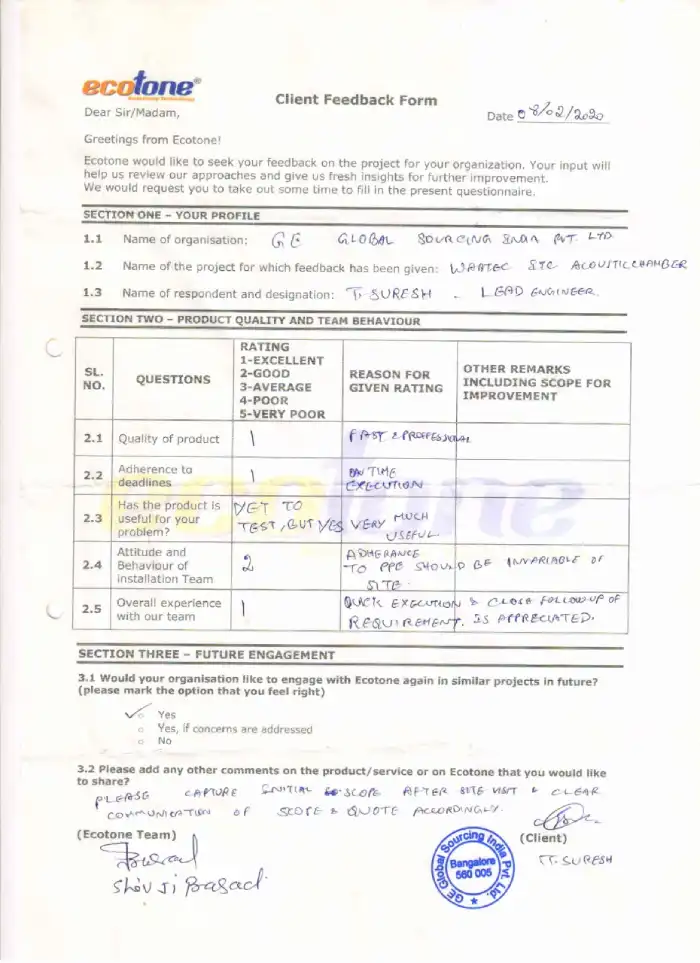

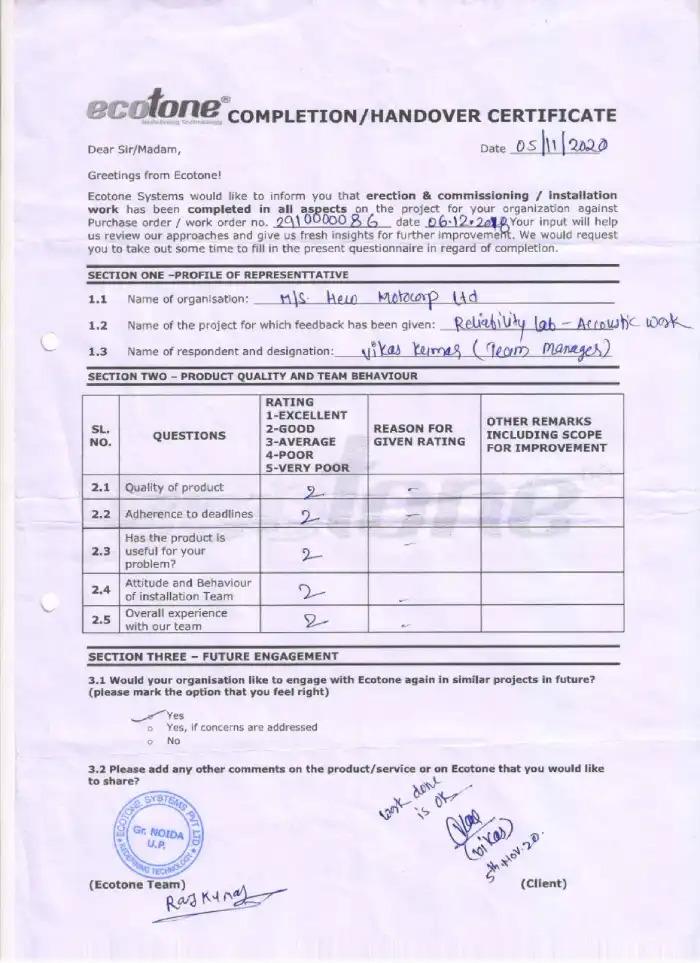

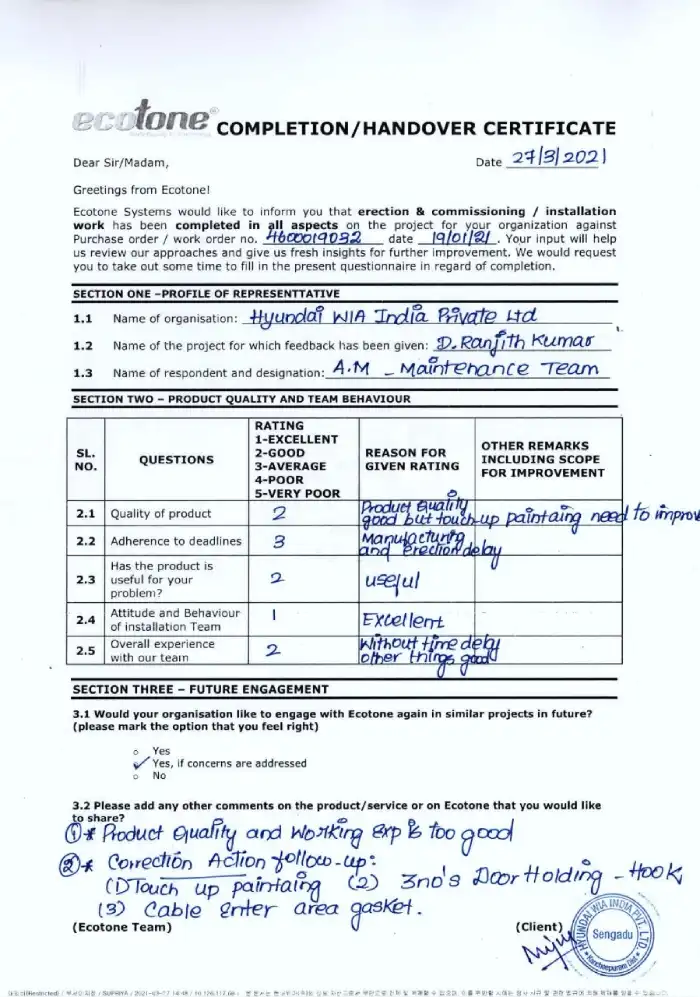

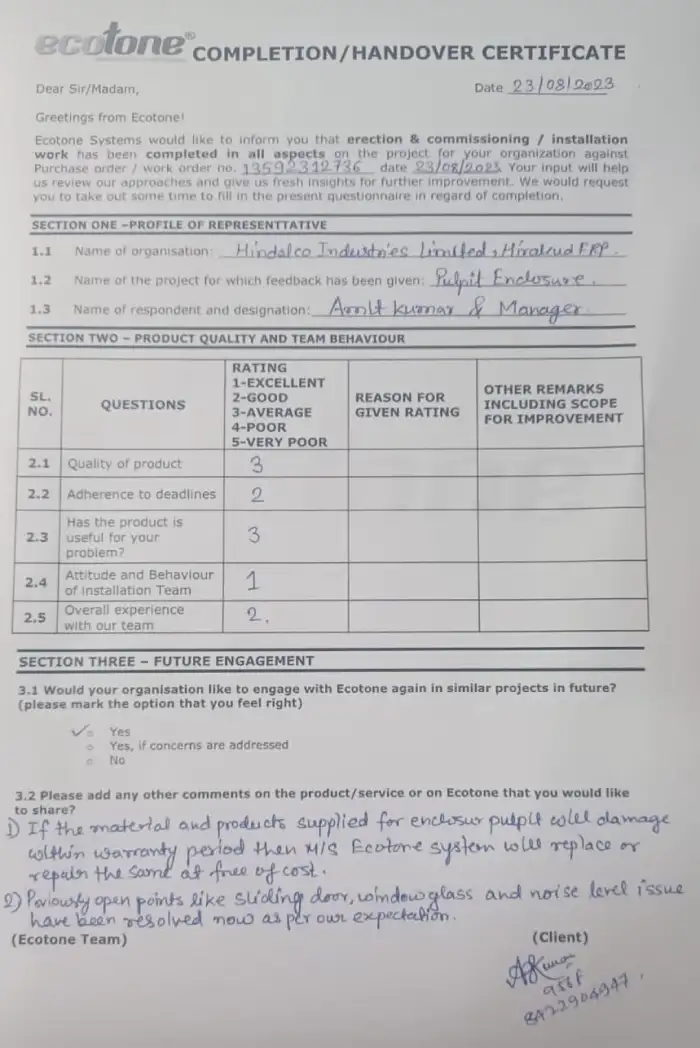

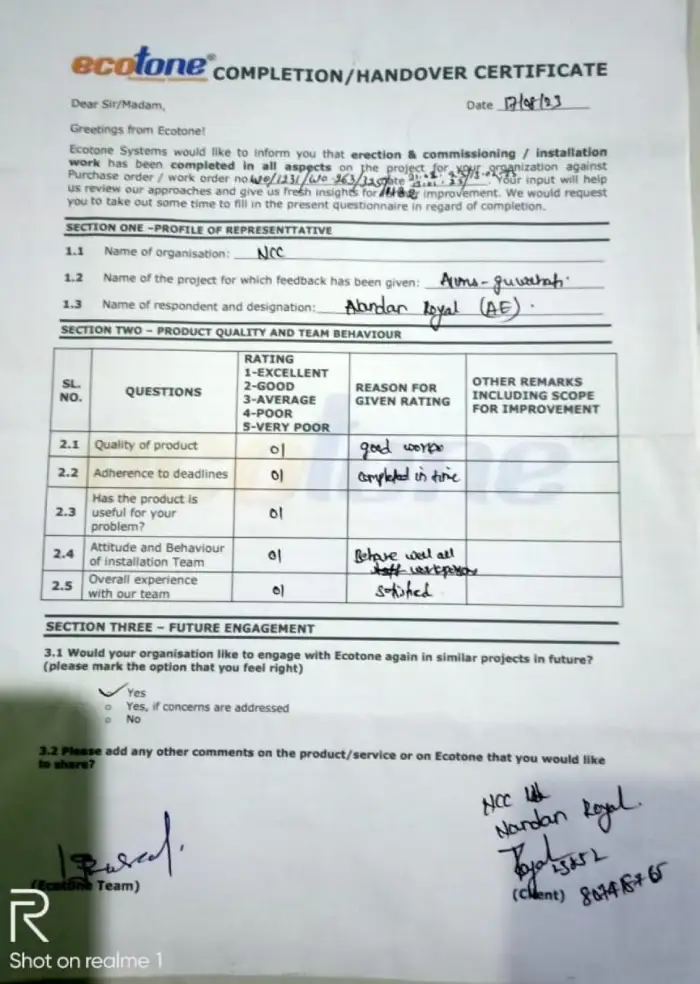

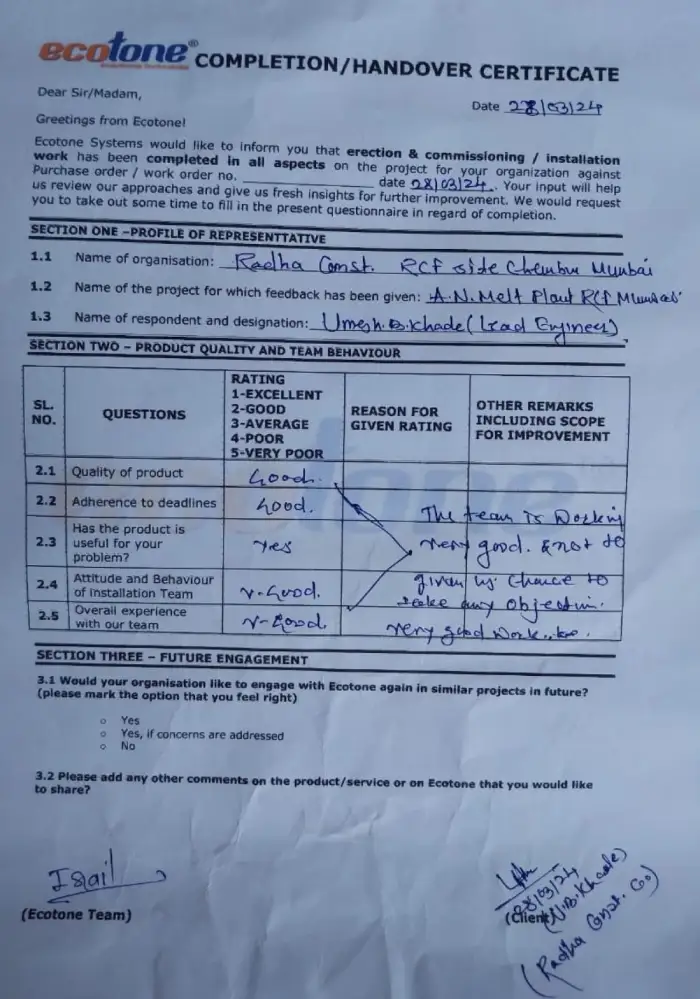

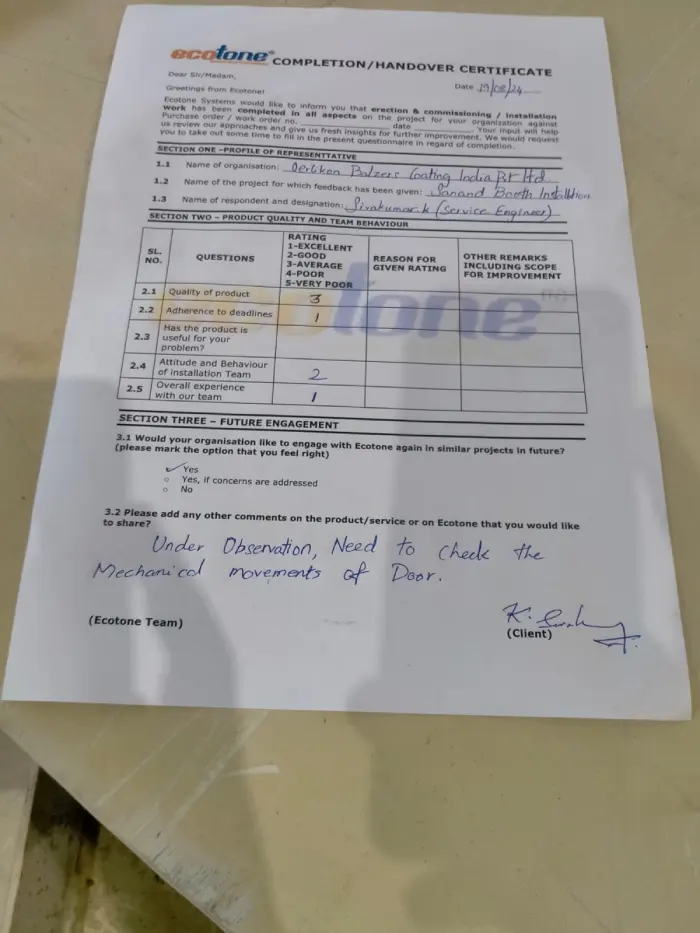

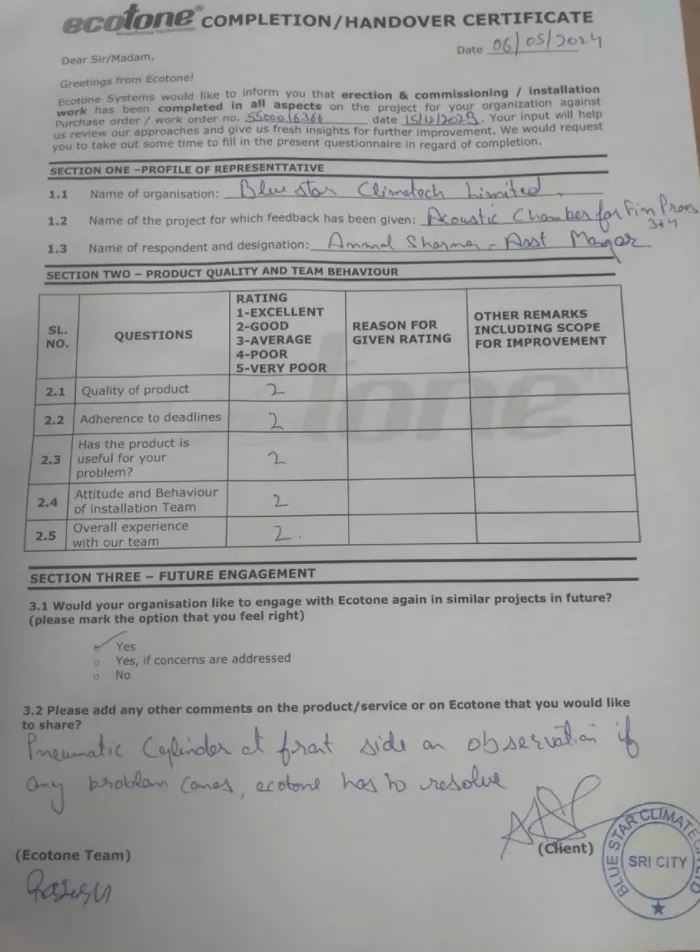

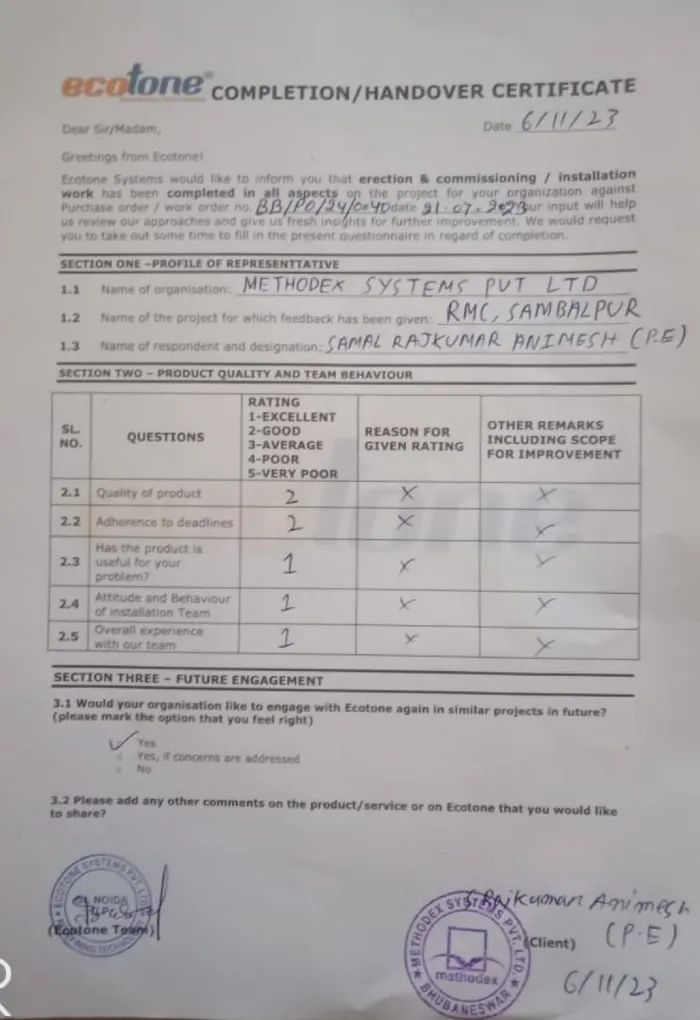

Feedback from Our Clients

At Ecotone Systems, we value every client relationship. Here’s what our clients have to say about their experience with our acoustic solutions, reflecting our dedication to quality, innovation, and trust

FAQ

ask us anything

What is the purpose of an NVH Chamber?

An NVH (Noise, Vibration & Harshness) chamber is used to measure and analyze the noise and vibration levels produced by vehicles, engines, appliances, or industrial machines. It helps manufacturers improve product quality and user comfort.

What industries use Semi Anechoic Chambers?

These chambers are widely used in the automotive, aerospace, electronics, consumer goods, appliance manufacturing, and industrial machinery sectors where precise acoustic testing is required.

What frequency range do Ecotone’s chambers support?

ECOTONE™ Semi Anechoic Chambers are typically designed with a 100 Hz cut-off frequency using ECO-10 Anechoic Wedges that offer up to 0.99 absorption across a wide frequency spectrum.

Can the chamber be customized?

Yes, ECOTONE™ provides complete customization, including chamber size, acoustic performance, wedge type, door design, ventilation, lighting, and testing configurations, based on client requirements.

Ecotone Completed Projects

Explore our portfolio of successfully delivered acoustic solutions across diverse industries. Each project reflects our engineering expertise, attention to detail, and commitment to high-performance noise control.