Best Anechoic Chamber Manufacturer in India

Ecotone Systems specializes in designing, fabricating, and installing high-performance Anechoic Chamber that comply with ISO 3744 and ISO 3745 standards. From concept planning to on-site execution, we offer complete turnkey solutions for various types of chambers, including Semi-Anechoic, Hemi-Anechoic, and Mini Anechoic Chambers.

What Is an Anechoic Chamber?

An anechoic chamber derived from the term “an-echoic,” meaning without echoes—is a controlled room designed to eliminate sound or electromagnetic reflections. It isolates internal activities from outside interference, ensuring that only direct sound is detectable. This makes the interior environment similar to being outdoors in a completely open free field.

Structurally, an anechoic chamber is a shielded enclosure with sound-absorbing or radio-wave absorbing materials applied to all interior surfaces. While some chambers are compact, most are walk-in rooms that allow engineers and researchers to conduct precise testing. These chambers are widely used across aerospace, automotive, electronics, and acoustic research industries. Their high insulation levels also make them ideal for audio or video recording that demands total isolation from external noise.

With a dedicated team of acoustic engineers, we ensure that each chamber delivers exceptional performance tailored to the client’s requirements. These specially constructed rooms absorb sound waves to eliminate echoes and reverberations, creating one of the quietest environments possible. The walls are lined with fiberglass wedges that absorb sound energy, preventing reflections and delivering a true free-field acoustic space.

Semi-Anechoic and Hemi-Anechoic Chambers

A full anechoic chamber absorbs energy from every direction, including the floor. To achieve this, all surfaces are fitted with specialized wedges, while a mesh or perforated floor is installed above a cavity to maintain accessibility. This floor is carefully decoupled from the building structure to prevent vibration and external interference from affecting measurements.

Semi-anechoic or hemi-anechoic chambers, on the other hand, feature a solid, hard floor. This design is ideal for testing heavy machinery such as vehicles, engines, industrial equipment, or appliances that cannot be supported by a suspended mesh floor. These chambers still provide excellent sound absorption on the walls and ceiling while allowing stable placement of bulky objects. Many recording studios and industrial test labs prefer semi-anechoic configurations for their practicality and versatility.

Industrial Applications of Anechoic Chambers

1. Noise Test Chambers

Noise Test Chambers help eliminate workplace noise by absorbing unwanted sound through advanced acoustic panels. They transform external noise into a calm, undisturbed acoustic environment suitable for testing office equipment, appliances, and communication devices with precision.

2. NVH (Noise, Vibration, and Harshness) Test Chambers

NVH Chambers are essential in manufacturing and automotive sectors. They are used for evaluating the noise and vibration characteristics of components such as engines, motors, speakers, and HVAC systems. These chambers support quality control and product development by ensuring optimal acoustic performance.

3. Audiometric Chambers

Designed for audiologists, acousticians, and architects, Audiometric Chambers provide strictly controlled acoustic conditions for hearing tests and research. These rooms meet stringent scientific standards and combine functional design with accurate sound isolation.

4. Semi-Anechoic Chambers

Semi-Anechoic Chambers reduce reflections, reverberations, and standing waves while offering a solid working surface. Their versatility makes them suitable for automotive testing, industrial equipment evaluation, and acoustic research requiring heavy load support.

5. Mini/Portable Anechoic Chambers

Mini Anechoic Chambers serve manufacturers of small devices and components, offering a compact and economical testing solution. They allow precise measurement of noise emissions and acoustic characteristics in a portable, controlled environment.

6. Engine Test Cell Acoustic Treatment

Engine test cells require specialized acoustic treatment to manage intense noise levels. This includes insulated wall linings, high-performance acoustic doors, engineered ducting for ventilation, exhaust systems, and soundproof viewing windows. Ecotone Systems integrates all these components to achieve a safe, efficient, and acoustically optimized engine testing environment.

Let’s Connect: Reach Out to Us

Have a question or idea? Fill out the form and we’ll get back to you soon!

Related Posts:

Contact Ecotone Systems for Professional Assistance

Looking for the right acoustic or noise control solution? Get in touch with Ecotone Systems and speak with our specialists. We provide reliable support, quick responses, and customized recommendations for your requirements.

Additional Acoustic Solutions Offered by Ecotone Systems

Ecotone Systems provides a wide range of advanced acoustic solutions designed to control, reduce, and manage noise in any environment. Along with our core products, we offer high-quality Noise Barriers for effective outdoor and industrial sound blocking, precision-engineered Acoustic Doors for strong sound isolation, durable Soundproof Curtains for flexible and affordable noise reduction, and robust Acoustic Enclosures designed to contain machine and equipment noise at its source. Each solution is built with reliable materials, easy installation options, and proven sound-control performance, helping businesses create quieter, safer, and more comfortable spaces.

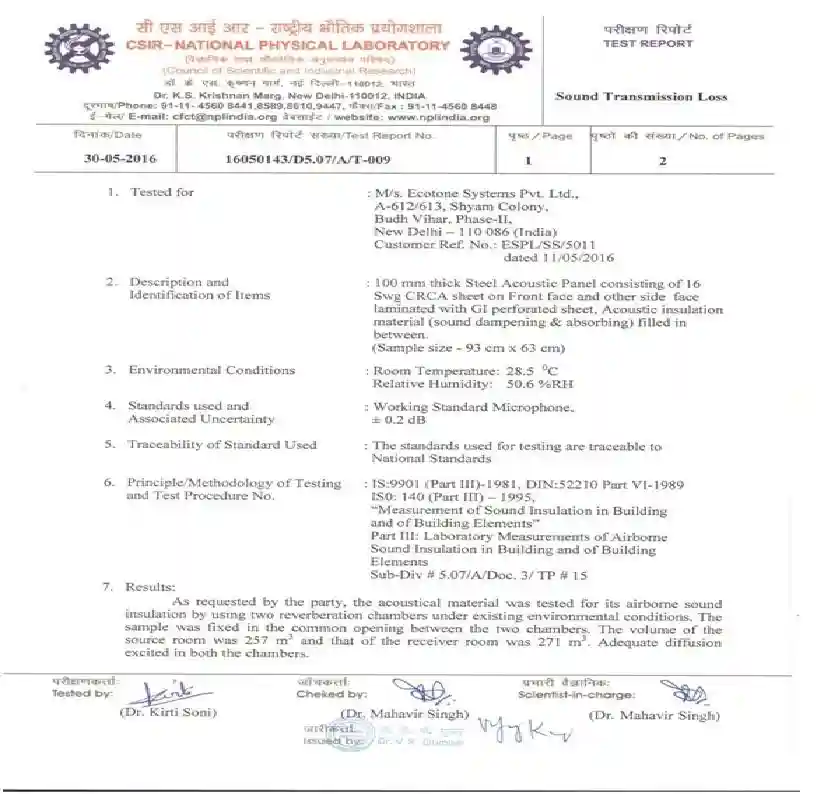

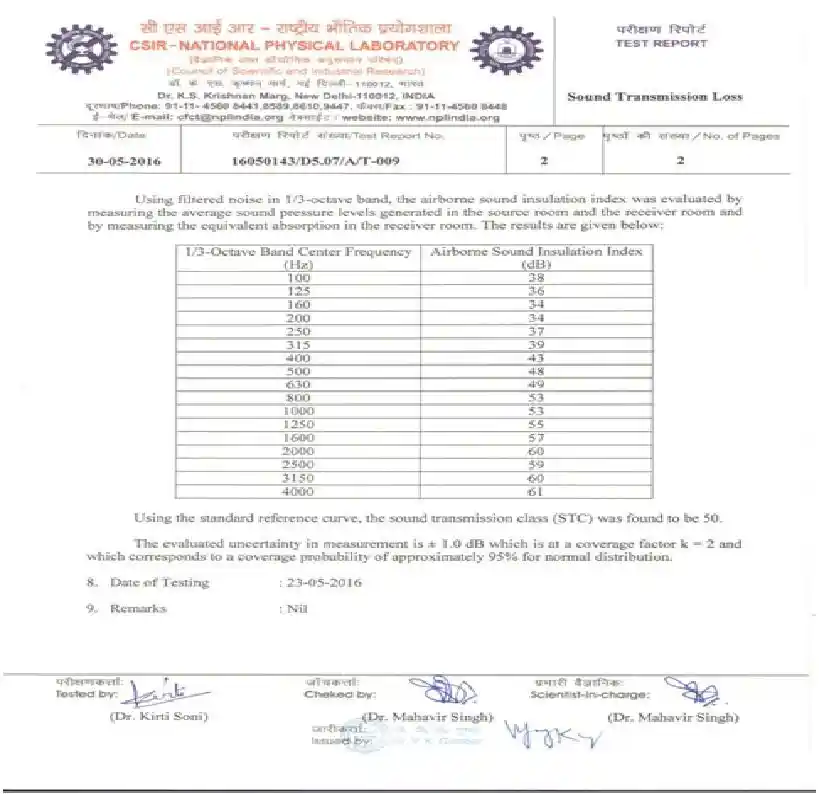

Anechoic Chamber Test Report

FAQ

ask us anything

What is the anechoic chamber used for?

What industries commonly use anechoic chambers?

Anechoic chambers are widely used in automotive, electronics, home appliances, research institutions, aerospace, and product development labs.

How long can a person stay in an anechoic chamber?

The longest that anyone has survived in the ‘anechoic chamber’ at Orfield Laboratories in South Minneapolis is just 45 minutes. It’s 99.99 per cent sound absorbent and holds the Guinness World Record for the world’s quietest place, but stay there too long and you may start hallucinating.

What types of anechoic chambers does Ecotone Systems offer?

Ecotone Systems provides Fully Anechoic Chambers, Semi Anechoic Chambers, Hemi Anechoic Chambers, and Portable Anechoic Chambers—each built to meet specific testing needs and ISO standards.

Ecotone Completed Projects

Explore our portfolio of successfully delivered acoustic solutions across diverse industries. Each project reflects our engineering expertise, attention to detail, and commitment to high-performance noise control.